|

Roughness upto 0.3nm by Surpper polishing

Excellent performance

Wavelength separation or combination can most easily be achieved by mirrors with special dichroic coatings. Application examples include the input of pump radiation to solid state lasers, the combination of alignment beams with high power laser output and the separation of harmonics from fundamental frequencies.

Commonly requested laser wavelength separations include:

532 / 1064 nm;920 / 1085 nm;1064 / 1543 nm

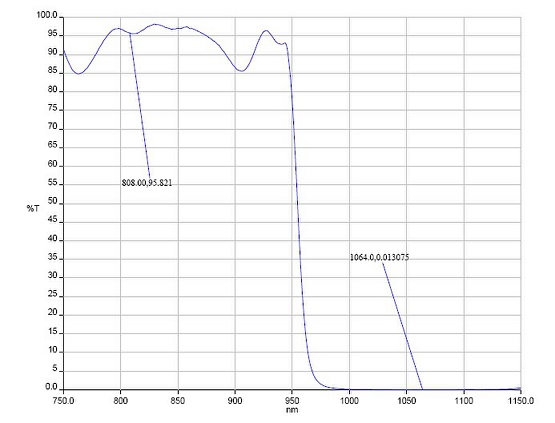

Laser dichroic mirrors must have defect free surfaces and high damage threshold coatings. They are designed and manufactured for a specific task. Our laser dichroic mirrors are thin film stacks which form an edge filter on one face of the mirror and an anti-reflection coating on the other face. Reflectance is at least 99.5% for the reflected wavelength and transmittance is over 95% for the second wavelength. Both long-pass and short-pass versions are available.

When specifying a dichroic mirror remember that the cut-off has a distinct slope and that the reflection region is limited . As a general guide the two wavelengths to be separated should be at least 100 nm apart and the reflection region should not extend more than 300 nm.

These mirrors can be supplied for 45° or normal incidence. They are usually supplied on BK7 or Fused Silica substrates of λ/10 flatness and 10/5 surface quality and have a high laser damage threshold of > 5J/cm2.

|

Material |

Fused silica, BK7, |

|

Surface Flatness |

λ/10 @633 nm |

|

Surface Quality |

20-10 scratch & dig laser quality |

|

Diameter Tolerance |

+0.00/ |

|

Thickness Tolerance |

±0.25 |

|

Parallelism |

30 arcsec |

|

Roughness |

Ra<0.3nm per customer request |

|

Coating |

R>99.8% @λ1, T>95%@λ2 |

|

Technology |

IBS coating |